To become a competitive filament twisting supplier of sewing thread, embroidery thread and technical yarn from high strength polyester & nylon 6.6 in global markets, especially in greige twisted yarn raw white on dye tube and bonded lubricated. The important factor is that COMPANY Farer runs daily OPERATIONS very carefully and responsibly, make her premium PRODUCTS come ture.

Farer always only use tier 1 quality materials in twisting process from the markets, no matter filament polyester yarn, high tenacity nylon yarn or other accessories such as thread dye tubes, lubricant and even packing pallets. Manufacturers of these materials are also major suppliers of most global top thread brands. We keep one very stable and long term business cooperation with our suppliers. Based on this, premium and stable quality of Farer's twisted yarn is guaranteed in the beginning.

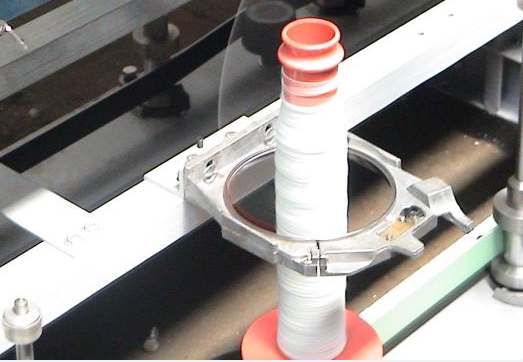

Responsibility is not only one slogan in Farer team, small details during thread twisting production are paid by attention, random wrong operation is treated as accident. Our daily manufacturing is guided by one set of clear, integrated and digital production running management which built from long term experience and exploration, Farer team and equipments could be kept to work under good condition continuously with this system. All equipments we installed are new and only use excellent spare parts such as Ring Travelers from Switzerland and Air-jet Splicers from Italy.

Above responsible culture, integrated production running system and excellent equipments are one of competitiveness of Farer.

Farer checks 100% tubes in visual quality control, from filament polyester and nylon yarn materials, semi-finished twisted yarns after twisting to finished threads after winding.

One laboratory is separated from workshop, to test yarns parameters and run #Spindles Monitor In Turn operation.

Farer cooperates with professional yarn and thread test laboratory CNTAC, to provide more accurate tests like sew-ability and color fastness for Farer's polyester filament sewing thread, nylon bonded thread and core spun sewing thread, both greige and dyed.

We respect our products, pack and transport them carefully, to protect yarn density and winding shape originated from our workshop. Since 2010, we started to pack our yarns by pallets, is one of pioneers who pack yarn products by plastic pallets with wonderful situation.

Continuous shipments in time is important for supply chain, we work with our shipping agent for years, schedule shipments with ture ships position on sea.

Safety in production is an important responsibility in Farer's daily running, we has built one complete set of production safety institution and operations under supervision by administration.

Employees are the hosts to run Farer, one complete organizational structure has been designed to specificate all positions, to match each position, Post responsibility, Performance Assessment and Promotion are fulfiled both managers and operators. #Skilled Operators Under Position Level Series contributes to the retention of outstanding employees, the formation of exceptional team, and the maintenance of workforce stability. One resposnible and skilled team in yarn twisting process is very benefit for guaranteeing premium quality sewing thread products.

As one part of Farer family, all employees and their family are cared in life, they are encouraged to participate in group activities and public benefit activities.

Occupational hazards are detected and health examination per year, Farer has built one complete set of occupational health operations of yarn and thread twisting factory under supervision by administration.

Program of Farer production plant is assessed and authorized by Department of environment protection. Farer will keep to shoulder the significant social responsibility to develop the green, environmental and ecology industry.