Farer is dedicated to twisting various high strength filament polyester, trilobal polyester, textured polyester and nylon 66, applied in high-end polyester sewing thread, embroidery thread and bonded thread.

Twisting is one of the most essential processes in sewing thread manufacturing. It directly determines the strength, uniformity, abrasion resistance, sewing performance, and the final appearance of the stitches. farerthread.com

What is twisting?

Simply put, twisting is the process in which two or more single yarns (or single fibers for filament threads) are rotated and consolidated around their own axis using twisting equipment. This process forms a single-ply sewing thread with a stable structure, certain strength, and elasticity.

- Physical Essence: Through twisting, friction and cohesion between fibers are generated, effectively converting the strength of the fibers into the strength of the yarn.

- Analogy: It is similar to twisting hemp into rope—several strands of hemp fibers are repeatedly twisted together to form a strong and durable hemp rope.

Objectives of Twisting

Imparts specific structural forms, physicomechanical properties, and aesthetics to yarns and plied threads.

Requirements for Twisting

1. Optimize strength, elongation, elasticity, softness, luster, and hand feel.

2. Diversify yarn structures.

3. Improve twisting efficiency.

4. Advantages of Twisted Yarns

- Mechanical Performance: High strength, elasticity, and resistance to mechanical stress during dyeing, finishing, and use.

- Spinnability: Adequate fiber length, friction, and cohesion.

- Comfort: Moisture absorption, thermal stability, and chemical resistance (to acids, alkalis, oxidants, etc.) enhance dyeability and wearability.

- Aesthetics: Vibrant dyeability ensures appealing final products.

Mechanism of Twisting

Twisting deforms fibers into helical spirals along the yarn axis, tightly binding the strands and altering their structural and mechanical properties. farerthread.com

Twist Measurement

1. Twist Level

The angular displacement of 360° between two cross-sections of a yarn forms one twist turn, commonly referred to as a single twist. The number of twists per unit length of the yarn is called the twist level.

2. Twist Factor

Twist level alone cannot be used to compare the degree of twisting in yarns of different thicknesses. Under the same twist level, thicker yarns exhibit greater fiber inclination than thinner ones. In practice, the twist factor is often used to represent the twisting intensity of yarns. The twist factor is a relative value that combines linear density (fineness) to indicate the degree of twisting, enabling comparison across yarns of varying thicknesses. It can be calculated using the yarn’s twist and linear density.

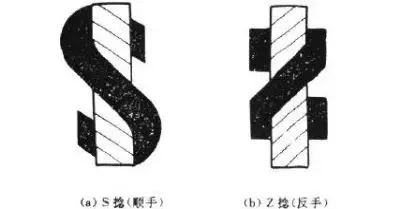

3. Twist Direction

Twist direction refers to the inclination of fibers in a single yarn or strands in a plied yarn after twisting. There are two types: S-twist and Z-twist.

S-twist: Fibers or strands slope from the bottom right to the top left, aligning with the middle stroke of the letter "S."

Z-twist: Fibers or strands slope from the bottom left to the top right, aligning with the middle stroke of the letter "Z."

In the twisting production of filament polyester sewing thread & embroidery thread and nylon 66 sewing thread, single yarns typically use S-twist, while plied yarns use Z-twist.

#Polyester sewing thread #Bonded nylon 66 sewing thread #Dyeing tube #Raw white on dye tube #Twisted yarn #Filament thread twisting #Thread twisting process